When using an electric carton edge peeling machine, several important considerations must be kept in mind to ensure optimal performance and safety.

Firstly, proper training is essential. Operators should be well-versed in the machine’s functions and safety protocols. This includes understanding how to adjust settings for different types of cardboard and recognizing the importance of maintaining a safe working environment.

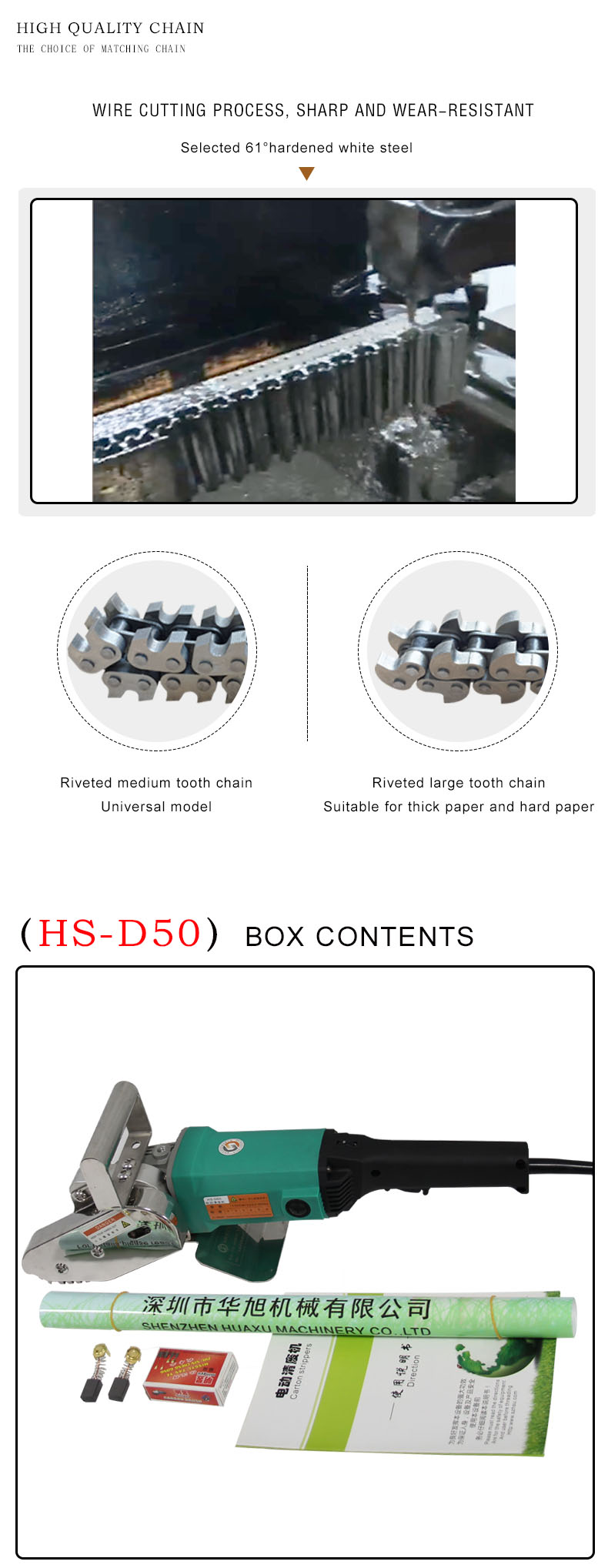

Regular maintenance is another critical aspect. Routine checks on the machine’s blades, motors, and electrical components can prevent unexpected breakdowns. Keeping the blades sharp ensures clean cuts, which is vital for the quality of the finished product. Additionally, lubricating moving parts can reduce wear and tear, extending the machine’s lifespan.

Safety features should never be overlooked. Ensure that all safety guards are in place and functioning correctly. Operators should wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to minimize the risk of injury.

Moreover, it’s important to monitor the machine during operation. Operators should remain vigilant for any unusual noises or vibrations, which could indicate a malfunction. If any issues arise, the machine should be stopped immediately, and a qualified technician should be consulted.

Lastly, proper material handling is crucial. Ensure that the cardboard is fed into the machine correctly to avoid jams or misalignments. By following these guidelines, printing factories can maximize the efficiency and safety of their electric waste stripping machine, leading to higher quality production and a safer workplace.

Firstly, proper training is essential. Operators should be well-versed in the machine’s functions and safety protocols. This includes understanding how to adjust settings for different types of cardboard and recognizing the importance of maintaining a safe working environment.

Regular maintenance is another critical aspect. Routine checks on the machine’s blades, motors, and electrical components can prevent unexpected breakdowns. Keeping the blades sharp ensures clean cuts, which is vital for the quality of the finished product. Additionally, lubricating moving parts can reduce wear and tear, extending the machine’s lifespan.

Safety features should never be overlooked. Ensure that all safety guards are in place and functioning correctly. Operators should wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to minimize the risk of injury.

Moreover, it’s important to monitor the machine during operation. Operators should remain vigilant for any unusual noises or vibrations, which could indicate a malfunction. If any issues arise, the machine should be stopped immediately, and a qualified technician should be consulted.

Lastly, proper material handling is crucial. Ensure that the cardboard is fed into the machine correctly to avoid jams or misalignments. By following these guidelines, printing factories can maximize the efficiency and safety of their electric waste stripping machine, leading to higher quality production and a safer workplace.

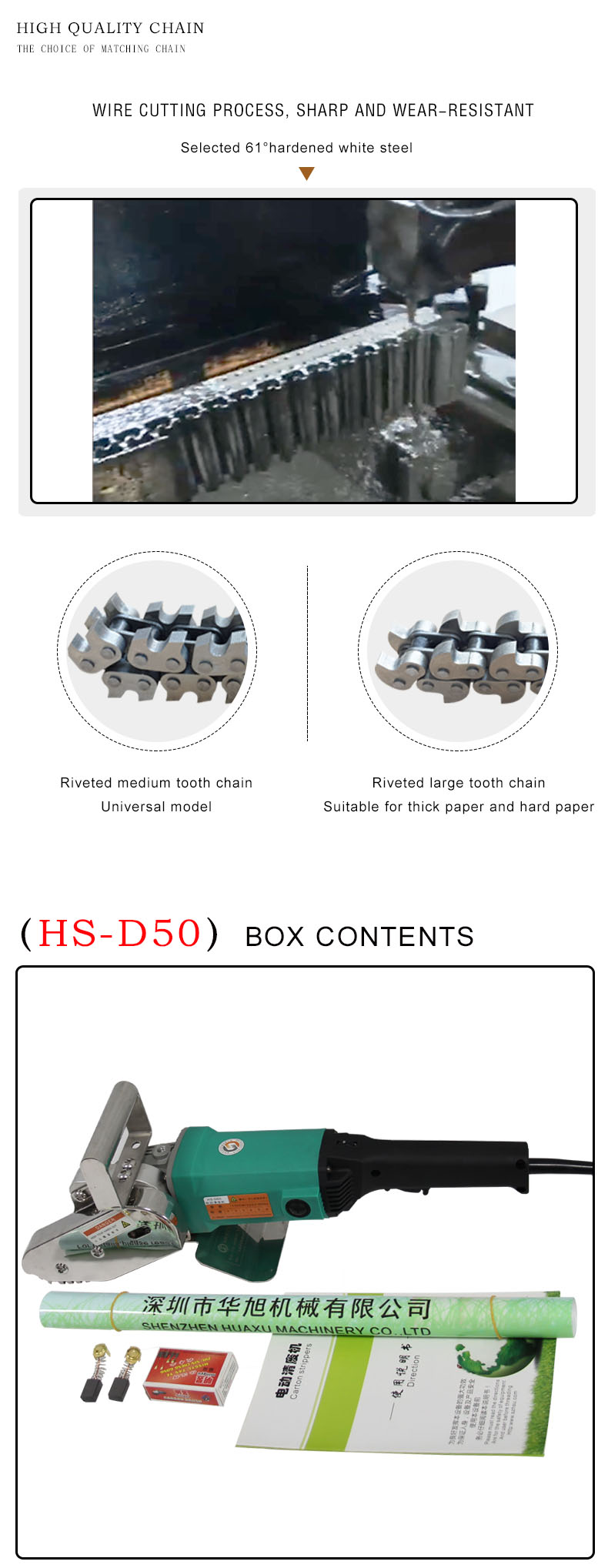

Shenzhen Huaxu Machinery Co., Ltd

Shenzhen Huaxu Machinery Co., Ltd