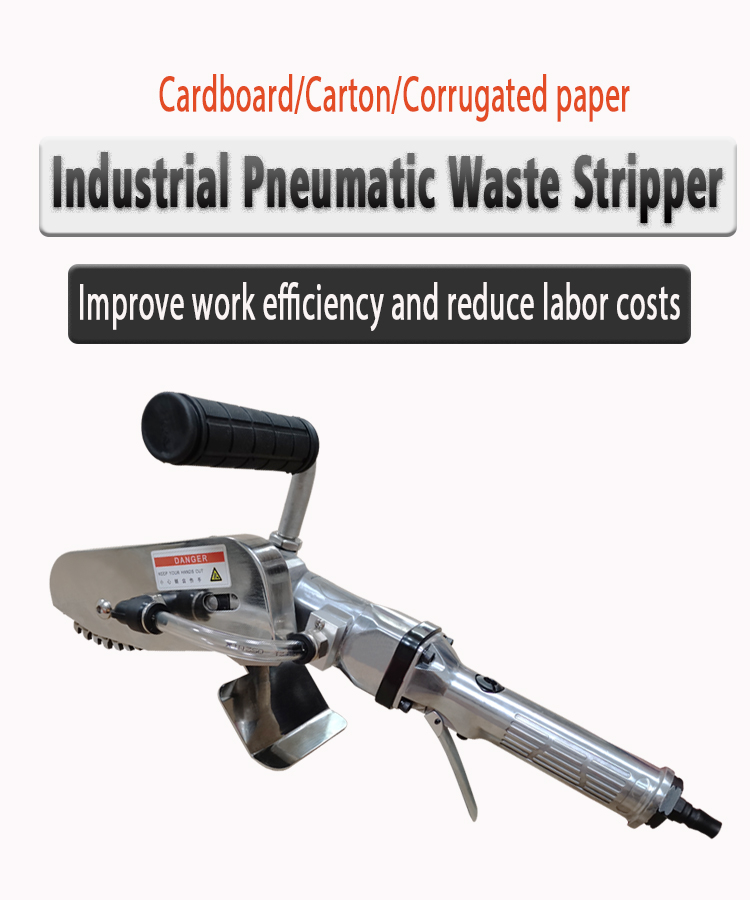

The pneumatic carton edge peeling machine is an essential piece of equipment in carton manufacturing plants, playing a significant role in enhancing production efficiency and product quality. This machine utilizes compressed air to operate, allowing for powerful and precise peeling of the edges of cardboard sheets, which is crucial for various packaging applications.

One of the primary uses of the pneumatic edge peeling machine is to streamline the production process. By automating the edge peeling task, it significantly reduces the time and labor required compared to manual methods. This increased speed allows manufacturers to produce a higher volume of cartons in a shorter period, which is essential in meeting the demands of a fast-paced market. The ability to quickly prepare cardboard sheets for further processing ensures that production lines remain efficient and responsive.

In addition to speed, the pneumatic machine ensures consistent quality. The use of compressed air provides uniform pressure, resulting in clean and precise edges. This consistency is vital for subsequent processes, such as printing and assembling, as it minimizes defects and enhances the overall appearance of the final product. A well-peeled edge not only improves the aesthetic quality of the cartons but also ensures better adhesion during the assembly process, leading to stronger and more reliable packaging.

Another significant advantage of the pneumatic carton waste stripping machine is its ability to reduce material waste. By accurately removing only the necessary amount of material, the machine optimizes the use of cardboard sheets. This efficiency not only reduces costs but also contributes to a more sustainable production process, aligning with the growing emphasis on environmental responsibility in manufacturing. Reducing waste is particularly important in an industry where material costs can significantly impact profitability.

Furthermore, the pneumatic system enhances worker safety. By automating the edge peeling process, it reduces the physical strain on operators, minimizing the risk of injuries associated with repetitive manual tasks. This focus on safety can lead to improved employee morale and productivity, creating a more positive work environment. Operators can work more efficiently without the fatigue that often accompanies manual labor, allowing them to focus on other critical tasks in the production line.

Moreover, the pneumatic edge peeling machine is designed to be user-friendly. With intuitive controls and minimal setup time, operators can quickly learn how to use the machine effectively. This ease of operation translates to less downtime and a more efficient workflow within the factory. Training new employees becomes simpler, allowing for a smoother transition and integration into the production process.

In summary, the pneumatic waste stripping machine serves multiple essential functions in carton manufacturing. Its ability to enhance speed, ensure quality, reduce waste, improve safety, and streamline operations makes it an indispensable tool for modern production facilities. As the demand for high-quality packaging continues to rise, investing in such technology is crucial for maintaining competitiveness in the industry. The pneumatic edge peeling machine not only boosts productivity but also contributes to the overall success and sustainability of carton manufacturing plants.

Shenzhen Huaxu Machinery Co., Ltd

Shenzhen Huaxu Machinery Co., Ltd