Groove Grinding Machine for Carton Flatbed Diecutter

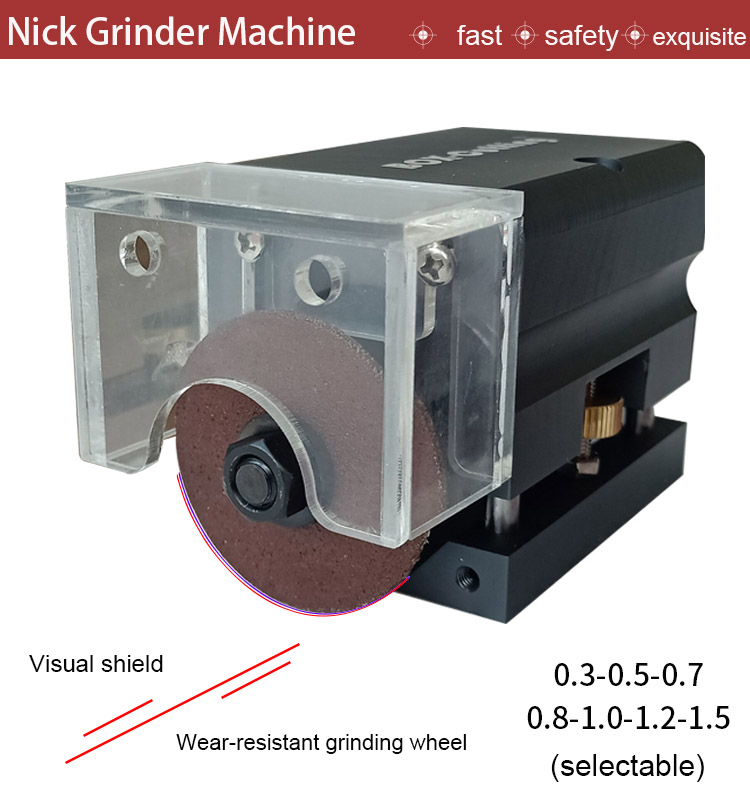

The Pneumatic Nick Grinder is an essential tool in the packaging and printing industry, specifically designed to enhance the efficiency and quality of die cutting processes. Its primary function is to create precise nicks on the cutting plates, which are crucial for achieving clean cuts and accurate shapes in various packaging materials.

One of the key benefits of the Pneumatic Nick Grinder is its ability to improve production efficiency. By automating the nicking process, it significantly reduces the time and labor required compared to manual methods. This efficiency allows manufacturers to prepare die cutting plates more quickly, enabling faster production cycles and meeting the demands of high-volume orders.

Additionally, the machine ensures consistent quality in the finished product. With precise grinding capabilities, it creates uniform nicks that enhance the performance of the die cutting plates. This consistency is vital for maintaining the integrity of the cutting process, as it prevents issues such as misalignment and uneven cuts, which can lead to material waste and increased production costs.

Moreover, the Easy Nick Grinder Machine contributes to the longevity of die cutting plates. By ensuring that nicks are created accurately, it reduces wear and tear on the plates during the cutting process. This not only extends the lifespan of the plates but also minimizes the need for frequent replacements, resulting in cost savings for manufacturers.

The machine is designed with user-friendly features, allowing operators to easily adjust settings for different plate sizes and specifications. This versatility makes it suitable for a wide range of applications, from simple designs to complex shapes, accommodating the diverse needs of manufacturers.

In summary, the Portable Groove Grinding Machine for die cutting plates plays a vital role in enhancing the efficiency, quality, and longevity of die cutting processes. Its ability to automate nicking, ensure precision, and reduce material waste makes it an invaluable asset in modern manufacturing facilities, helping companies meet the growing demands of the packaging industry while maintaining high standards of quality.

Shenzhen Huaxu Machinery Co., Ltd

Shenzhen Huaxu Machinery Co., Ltd